2006

A further milestone has been reached: Spilling can now also offer steam turbines for the conversion of waste heat into electricity. One of their outstanding features is their suitability for saturated steam operation.

1999

In all series of steam engines, Spilling is now focusing on the introduction of dry-running technology (oil-free steam).

From 1978

The Spilling engines are continuously further developed and are now also used internationally as natural gas expansion engines in the utility industry to exploit the pressure gradient between the gas transport pipeline and the consumer network.

1956

Spilling builds the first steam compressor, thus laying the foundation for future developments.

Since 1950

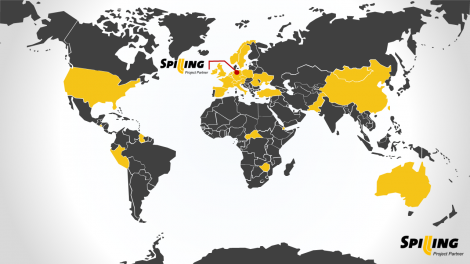

Spilling produces with the steam engine reliable combined heat and power plants, that are successfully used in over 50 countries around the world.

1945 to 1950

Spilling can quickly pick up speed again after the war and, with the Spilling modular steam engine, makes a name for itself as a flexible driving machine for generators and working machines.

1930 to 1945

Spilling has always positioned itself successfully in the market with the continuous development of systems. For example, the open steam engine is further developed to an encapsulated steam engine with forced oil lubrication.

1918 to 1936

Spilling designs and builds new piston steam engines for ship propulsion.

1890

A ship machinery repair business is founded in the Hamburg free port on Kleiner Grasbrook. This is the birth of the Spilling company.