Green electricity from Spilling.

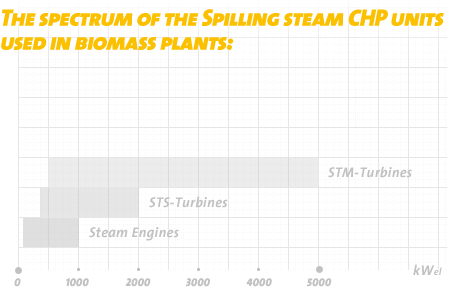

Spilling steam engines and steam turbines have proven themselves as prime movers for smaller and medium-sized biomass power generation plants in industry and regional power supply. They are preferably operated as combined heat and power plants.

Spilling steam engines are usually used in combination with boilers with moderate "live steam conditions" or saturated steam boilers and then especially when the steam mass flow or power take-off are subject to significant fluctuations. Spilling steam engines can be serviced by the company's own staff and are therefore also suitable for use in remote locations.

Multi-stage Spilling steam turbines are installed where the advantages of the Spilling steam engine are not relevant or the requirements of the entire plant demand a turbine. These are then designed as back pressure turbines or also as condensing turbines for biomass power plants. This concerns e.g. applications with larger, constant mass flows and higher live steam pressures and temperatures.

Steam CHP units used in biomass plants are suitable for

- Pellet factories

- Biomass cogeneration plants

- Wood industry

- Rice mills

- Palm oil mills