CHP for optimised fuel utilisation.

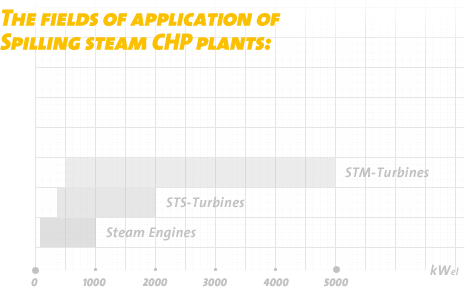

Spilling steam engines and back pressure turbines are always used in process and heating steam systems, when the pressure difference between the boiler plant and consumers is to be used for extracting mechanical or electrical power.

This kind of power harnessing convinces with an extremely low additional fuel requirement to generate electricity. In comparison with conventional "condensation energy", combined heat and power contributes to a significant reduction of CO2 emissions through low energy costs.

Spilling steam engines and back pressure turbines can be used in all kinds of branches and processes. A new installation is by no means always necessary when the entire boiler house is modernised or newly planned – existing plants can also be retrofitted with a power plant in order to realise electrical power generation in-house to optimise the energy balance of a company.

As a rule, the investment in such a retrofit is manageable and has a high economic benefit. Depending on the region, the economic efficiency of the CHP plant can be distinctly raised using systematic funding with e.g. CO2 certificates, tax benefits or compensation for electricity fed into the grid.

The use of CHP is worthwhile for branches in the fields

- chemical industry

- process engineering

- paper industry

- textile industry

- food industry

- breweries

- primary industries

- district and local heating supply